ENSEMBLES

Is Ensemble Modelling the Future of CEOR Simulation?

Ensemble modelling attempts to capture the impact of subsurface uncertainty on predictions of reservoir performance. This uncertainty arises from the fact that many reservoir parameters are not precisely known. For example, porosity, permeability and other reservoir properties are only known in a statistical sense. The ensemble of simulation cases should reflect this uncertainty, but also be constrained by observed production data. That is, each realisation in the ensemble is a sample of simulation input parameters drawn from the prior distributions of reservoir properties, but further constrained to lie within the subspace of parameters consistent with the production data. Using these ensemble cases to predict reservoir performance provides a realistic representation of the statistical variation of possible future production given the subsurface uncertainty.

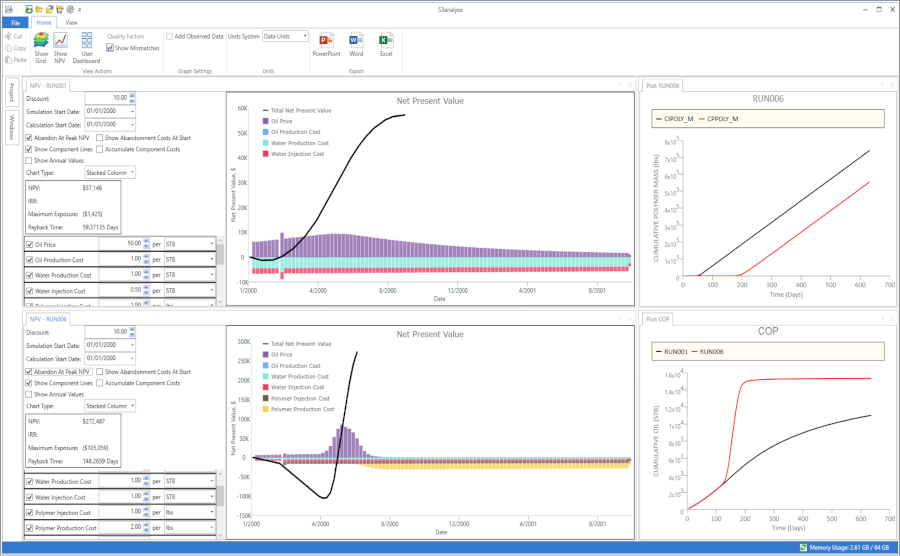

One of the key measures for evaluating alternative field development plans is the Net Present Value (NPV), which discounts future revenue and expenditure back to their present value, to provide a consistent basis for comparison of long-term projects. This is especially important for Chemical EOR projects, where initial capital expenditure on chemical infrastructure, and ongoing chemical costs have an important bearing on the viability of CEOR projects. For example, Figure. 1 shows the NPV View in Sciencesoft’s S3analyse software for waterflood (top) and polymer flood (bottom) simulation cases, for the same reservoir model. The operating costs (the costs of injecting and producing fluids and chemicals) and the oil price are specified, along with the discount rate, taxes, royalties, etc. Using these values, and the simulated injection and production rates, the change in NPV with time is calculated. The stacked histogram bars show the contributions to the NPV from different sources in each time period. Note that the NPV for the polymer flood is significantly negative at early times as a result of the polymer cost, before the increase in oil production (caused by the banking of oil by the injected polymer) kicks in.

Figure 1: NPV View in S3analyse showing the contributions to NPV over time for a polymer flood simulation case

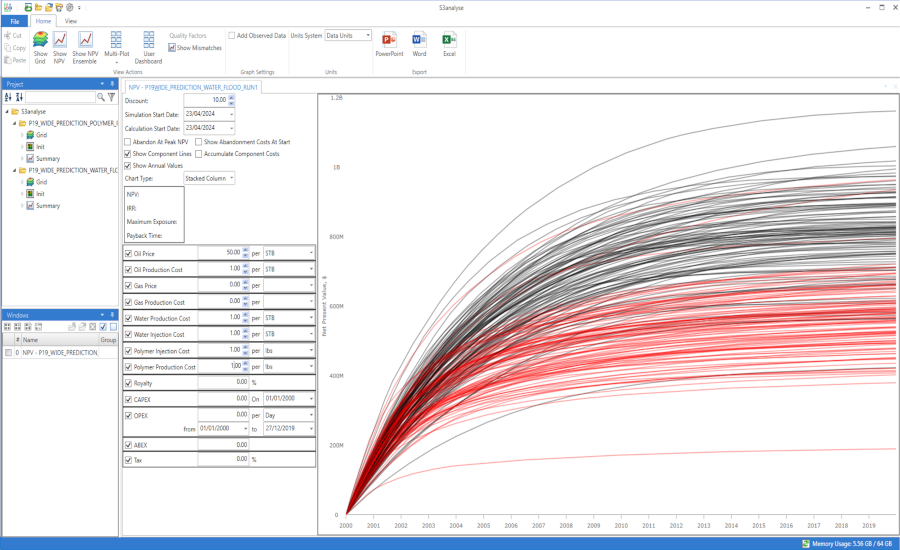

Failing to model the reservoir uncertainty can lead to an incorrect estimation of the value of a project. To illustrate this, consider the ensemble NPV plots from S3analyse in Figures. 2 and 3. These show the effect of subsurface uncertainly on the calculated NPV for a pilot study (based on a sector of a full-field model), comparing the NPVs for a simple waterflood and a polymer flood. The ensemble that is the basis of this study was generated by selecting a pilot region from a full-field model and automatically generating sector models (using Sciencesoft’s S3quickbuild software) from each case in the full-field ensemble for the pilot region. These were each then run with water injection and polymer injection. Figure. 2 compares the spread of NPV values for the waterflood (red) and polymer flood (black), for each ensemble case. The benefit of the polymer flood is clear, although the spread in NPV is wide.

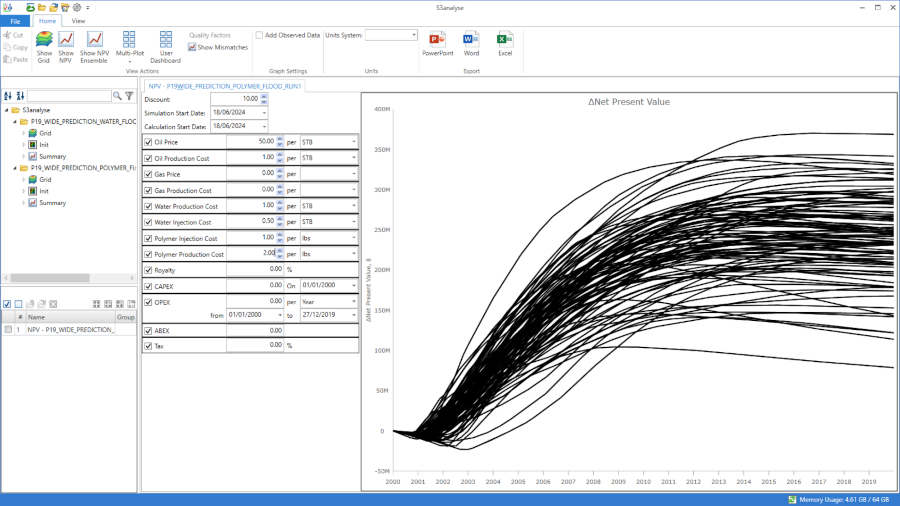

Figure. 3 shows the net increase in NPV for the polymer flood over the simple waterflood. Again, the benefit of polymer flooding is unarguable (showing an NPV increase of around $225M), although the range of the NPV increase over the ensemble is quite large.

Figure 2: Comparative plot of NPV in S3analyse for polymer flooding (black) and waterflooding (red) applied to the uncertainty ensemble cases

Figure 3: NPV-difference ensemble plot showing the increase in NPV for polymer flooding relative to waterflooding for each ensemble case

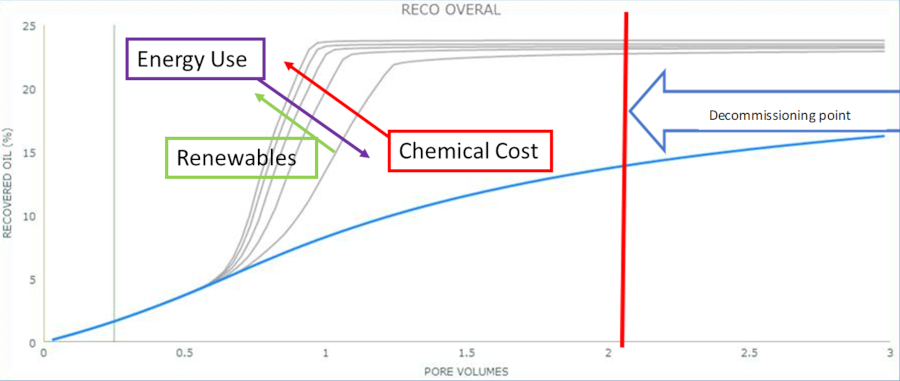

An important application of Chemical EOR is the reduction of energy consumption by reducing the separator power requirements that result from high water cuts. Energy consumption is a strongly nonlinear function of the produced water cut, so using CEOR to reduce water cut can have a significant environmental and cost benefit. This is illustrated in Figure. 4, which shows the oil recovery for polymer floods with a range of injected polymer concentrations, from zero (blue line) to 0.5 wt%. Oil production is significantly accelerated with higher polymer concentrations, leading to lower water cuts and therefore lower energy consumption and environmental impact. Again, correctly estimating the potential benefit of CEOR for reducing energy and environmental costs really requires the use of ensemble modelling. Using ensemble modelling in the evaluation of field development plans can result in fewer and better-targeted wells, with large savings in energy consumption and time to extract the oil. Reducing the time from drilling to the decommissioning point (see Figure. 4) helps to lower the overall carbon footprint of the reservoir as well as producing a faster and more profitable return. This is especially true when using CEOR processes, where the cost of chemicals can be significantly reduced, resulting in a de-risking of the CEOR project.

Figure 4: Polymer flooding can significantly decease energy use

| S3chembuild | |

| S3schedule | |

Upcoming Events

Latest News

SUBSCRIBE TO OUR MAILING LIST

Contact Us

To apply for a job at Sciencesoft please email jobs@sciencesoft.com with your CV and a covering letter.